|

Mud Motors |

|---|

|

|

|

|

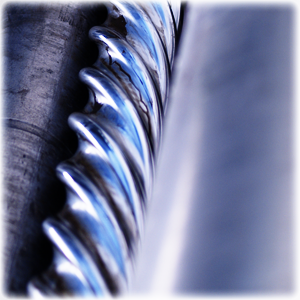

Components of the IPS downhole motors can be selected to optimize performance in each type of drilling conditions and some are interchangeable - stabilization sleeve (plain or stabilized) and a deflector elbow (known as a "bent housing") allows one to rotate and drill vertical sections, as well as the tangential and horizontal sections of the well, sliding at predetermined points to deviate the hole trajectory. Combination designs of the stators and rotors enable us to select the physical and chemical properties that allow the mud motors to operate in high temperatures and oil based emulsion muds through the use of certain elastomeric components in the stators. Drilling Performance: The versatility and power of IPS Mud Motors makes them ideal for performance in drilling and directional drilling straight holes, increasing the rate of penetration (ROP) and reducing wear of the lining due to a lower rotation the string. Directional Drilling: The compact design and high torque characteristics of the engines IPS background make them suitable for conventional directional drilling-navigation through a predetermined geometric path. |

IPS Mud Motors are designed according to the requirements of our directional drillers and clients, with particular emphasis on its resistance to extreme environments, simplicity and proven technology resulting in high performance. Operational requirements were established in conjunction with drilling companies and our customers. Through knowledge and experience, IPS Engineers have focused on improving the reliability, performance and maintenance costs that have yielded improvements in drilling efficiency at lower cost. The IPS downhole motor consists of four (4) main components:

IPS Mud Motors are designed according to the requirements of our directional drillers and clients, with particular emphasis on its resistance to extreme environments, simplicity and proven technology resulting in high performance. Operational requirements were established in conjunction with drilling companies and our customers. Through knowledge and experience, IPS Engineers have focused on improving the reliability, performance and maintenance costs that have yielded improvements in drilling efficiency at lower cost. The IPS downhole motor consists of four (4) main components: