|

Drill Collars |

|---|

|

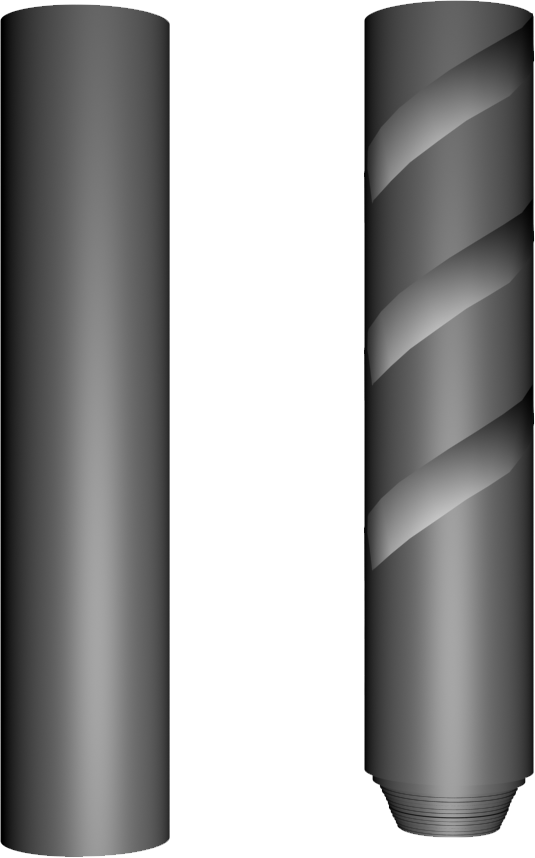

Steel Drill Collars - DC –The tubular steel drill collars are heavy and stiff, are used in the bottomhole assembly (BHA) to provide rigidity and weight on bit. |

The surface of the steel drill collars can be smooth or spiral; in directional drilling, the preference is to use spiral drill collars. The spiral groove that is machined on the collar reduces the contact area with the wall in a 40% (decreasing the overall weight by only 4%), which greatly reduces the probability of experiencing differential pipe sticking |

|

Short Steel (Pony) Collars |

|---|

|

Are nothing more than a shorter version of a steel drill collar, which may be manufactured as single pieces or they can cut from a large steel drill collar - so as to obtain two or more drill collars short. For directional drilling, the Non-Magnetic Pony Collar has its greatest application in the Packed Hole BHA’s. Normally, the Pony Collars come in various lengths (5 ', 10', 15 ') which are supplied by the directional drilling company. |

Non-Magnetic Drill Collar - NMDC |

Magnetic measurement instruments that are run in the hole must be placed into a NMDC of sufficient length to allow measurement of the earth's magnetic field, without there being any magnetic interference. |